[Main] [Project Deliverables ] [Progress Log] [Methods/Research ] [References/Links]

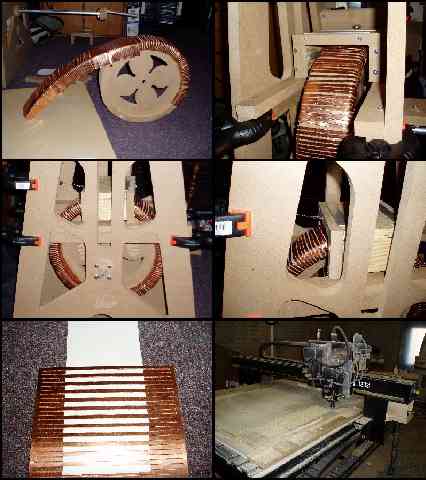

The Maglev Test Bench is a fixture used to test the Inductrack system. The wood (Nor Board) has been donated by Midwestern Wood Products Co. A computer numerically controlled (CNC) router was used to cut the parts to create the test wheel, and the copper track. This CNC is shown in figure 1.

Figure 2 shows the Maglev Test Bench created.

The laminated copper track requires precision machining in order to create grooves closely spaced, and terminating prior to the ends of the sheet. A ‘V’ bit has been used to create the small grooves between conductive strips. The ‘V’ bit allows for the smallest groove possible by a router. The ‘V’ bit is shown in figure 3.

This procedure has been found to be very difficult. The copper must be kept flat, held down, and cut slowly. The creation of a piece of track is very time consuming. Figure 4 shows a portion of the track.