[Main] [Project Deliverables ] [Progress Log] [Methods/Research ] [References/Links]

Richard F. Post, Physicist at Lawrence Livermore National Laboratory, was the creator and team leader of the first Inductrack developed under the U.S. Department of Energy that was demonstrated in 1998. The Inductrack method was created, tested, and proven to work on a small scale level with a 20 meter track. The track only had a burst propulsion system for the first meter of the track.

Post was then contracted by the National Aeronautics and Space Administration (NASA) to create a test track for launching rockets. He is currently a part of the Low-Speed Urban Maglev Program under the U.S. Department of Transportation, Federal Transit Administration along with General Atomics (GA), Hall Industries, and many other companies. The Urban Maglev Project is to create a full scale low speed Maglev train utilizing permanent magnets. The project is still in the development stage.

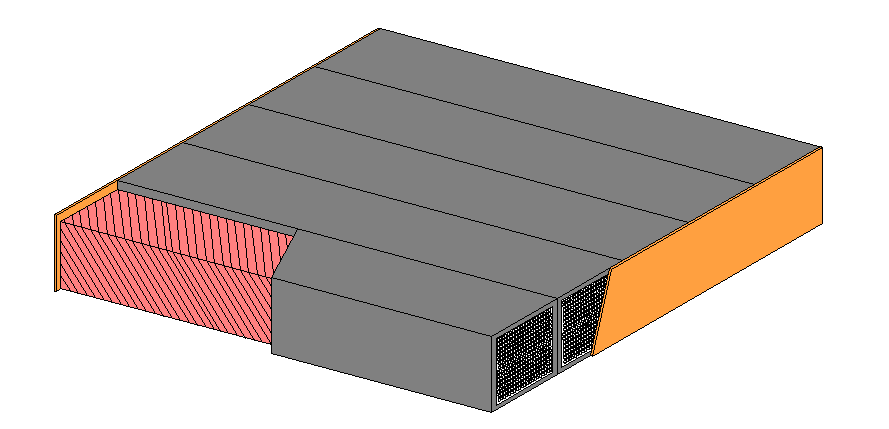

The inductive track can be made by different methods. The three main methods being investigated are wrapped wires, wire rungs, or laminated sheets.

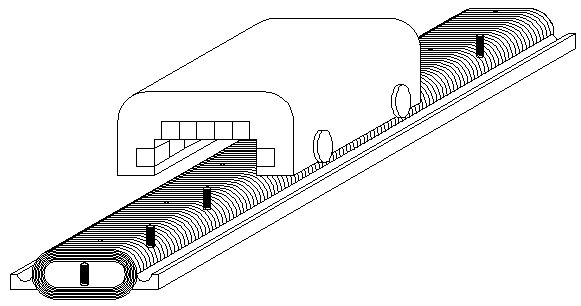

The wrapped wire method or array of inductors method was utilized to create the first Inductrack at Lawrence Livermore National Laboratory. The track is shown previously in figure 5. An illustration of the Array of Inductors method is illustrated in figure 7.

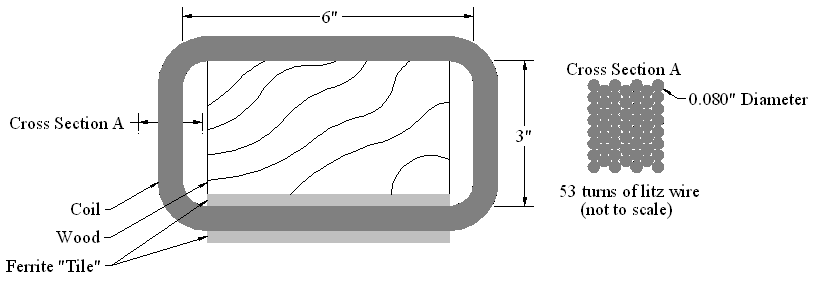

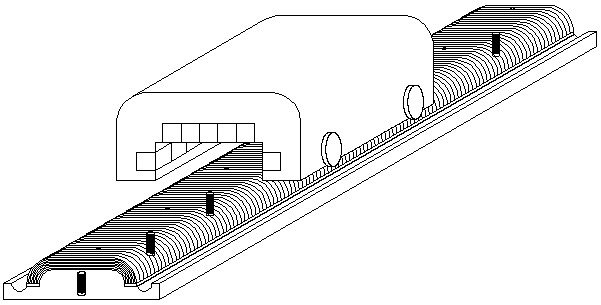

The first track used at the Livermore National Laboratory utilized 53 turns of 0.080” diameter Litz-wire to create ½” deep coils. The coils were 6” wide, and 3” tall. A wood block was used to give the coils strength. Ferrite tiles were used above and below the bottom portion of the coils to load the inductive coils yielding a higher inductance. Later, ferrite beads were used on the lower portions of the inductors instead of ferrite tiles. The schematic drawing of the Inductrack model track is shown in figure 8, [8].

The Array of Inductors method is hard to manufacture, and expensive to produce. For this reason, the Array of Inductors method is not being pursued.

The wire rung method is currently being used for the Low-Speed Urban Maglev Program, because of its low cost and ease of being produced and manufactured [5].

The wire rungs are created by using bulks of insulated wire placed in tubes. The rungs have been produced by Litz-wire. The wire have been transposed, pressed via rolling and specialized tapping into 2" square stainless steel tubes [6]. Stainless steel tubes provide structural support for levitating the train. The ends of the tubes, where the wires end, are soldered to copper strips to short the wires together. This creates the equivalent of laminated sheets of copper with grooves placed to guide the eddy currents. An illustration of the rungs is shown in figure 10.

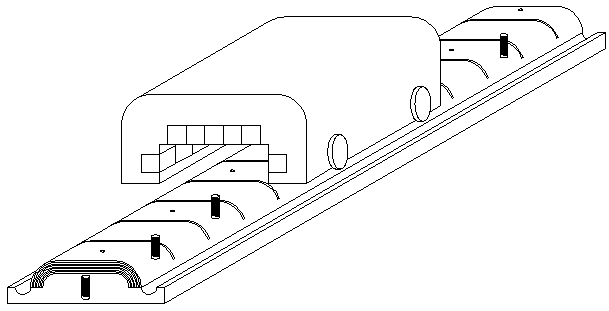

Stainless steel tube exoskeletons are not needed if a different method is used for rails. A single rail, monorail, can be used with the levitation supported below the wire by bending it around the supporting structure. An illustration of this method is shown in figure 11.

The physics of the Inductrack work with the properties of the Halbach array. All physics and equations being used have been developed by the Inductrack team at Lawrence Livermore National Laboratory [11].